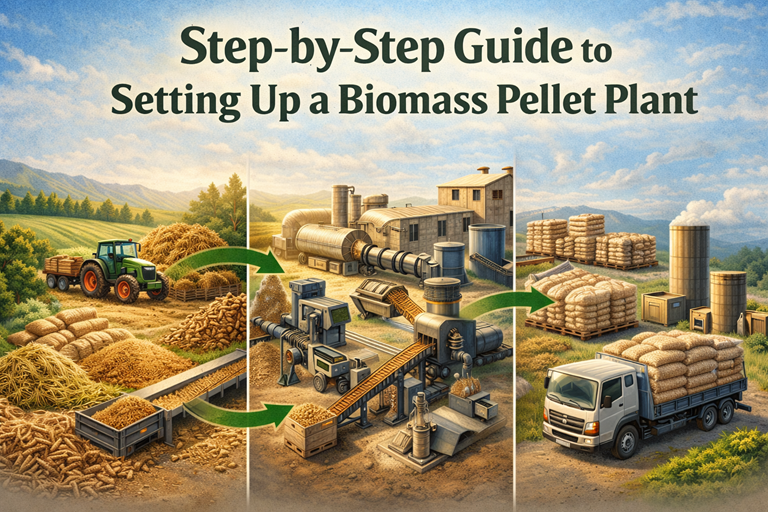

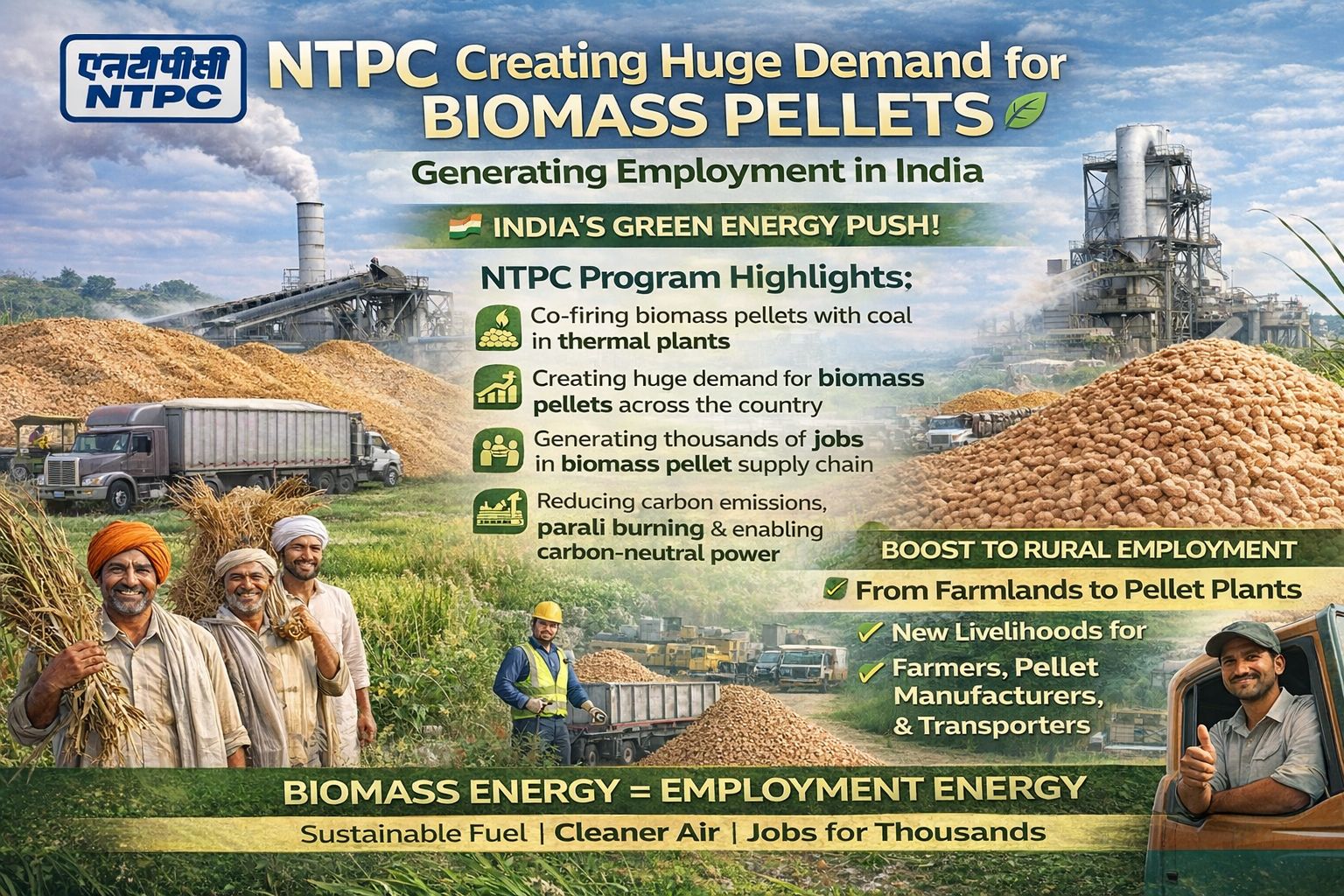

With rising fuel costs and increasing pressure to reduce carbon emissions, biomass pellets have emerged as a clean, renewable, and economical alternative to coal and fossil fuels. Governments, industries, and power plants are actively shifting toward biomass-based energy solutions. Setting up a biomass pellet plant not only supports sustainability but also opens strong business opportunities.

This guide walks you through each step involved in setting up a biomass pellet manufacturing plant, from planning to production.

Step 1: Understand Biomass Pellets & Their Demand

Biomass pellets are compressed biofuels made from agricultural residues and organic waste such as rice husk, sawdust, straw, bagasse, and wood chips. They are widely used in:

- Industrial boilers

- Thermal power plants

- Brick kilns

- Food processing industries

Growing environmental regulations and coal replacement policies are driving continuous demand for biomass pellets.

Step 2: Selection of Raw Materials

- Choosing the right raw material is critical for pellet quality and profitability.

- Common raw materials include:

- Rice husk

- Wheat straw

- Paddy straw

- Sawdust

- Groundnut shells

- Sugarcane bagasse

- Key parameters to consider:

- Moisture content (ideal: 10–15%)

- Availability throughout the year

- Transportation cost

- Calorific value

Step 3: Plant Capacity Planning

Decide plant capacity based on:

- Market demand

- Raw material availability

- Investment budget

Typical plant capacities:

- Small scale: 1–2 TPH

- Medium scale: 3–5 TPH

- Large scale: 6–10+ TPH

Capacity planning helps in machinery selection and land requirement estimation.

Step 4: Machinery & Equipment Required

A standard biomass pellet plant consists of the following machinery:

Raw Material Handling System

– Conveyor belts, loaders, storage bunkers

Dryer System

– Rotary dryer or flash dryer to reduce moisture

Grinding Machine

– Hammer mill or crusher for size reduction

Pellet Mill

– Ring die or flat die pellet machine

Cooling System

– Counterflow pellet cooler

Screening & Packing System

– Vibrating screen, bagging machine

Automation can further improve efficiency and reduce manpower costs.

Step 5: Land & Infrastructure Requirement

A biomass pellet plant requires:

- Open area for raw material storage

- Covered shed for machinery

- Power connection (industrial load)

- Water source for cooling & dust control

Approximate land requirement:

- 1–2 TPH plant: 10,000–15,000 sq. ft.

- 5 TPH plant: 25,000–30,000 sq. ft.

Step 6: Power & Utilities

Power consumption depends on plant size and automation level.

- Average consumption: 90–120 units per ton

- Backup power (DG set) recommended

- Dust collection & fire safety systems mandatory

Step 7: Quality Control & Standards

Consistent pellet quality ensures repeat buyers.

Key quality parameters:

- Pellet diameter & length

- Bulk density

- Ash content

- Moisture percentage

- Calorific value

Regular lab testing and proper process control are essential.

Step 8: Cost & Investment Overview

Investment depends on capacity and automation.

Indicative cost range:

- 1 TPH plant: ₹35–50 lakh

- 3–5 TPH plant: ₹1.2–2.5 crore

Operating costs include raw material, labor, electricity, maintenance, and transportation.

Step 9: Marketing & Sales Strategy

Potential customers include:

- Industrial boiler users

- Power plants

- Export traders

- Biomass fuel aggregators

Digital marketing, direct industry tie-ups, and long-term supply contracts help ensure steady revenue.

Step 10: Compliance & Sustainability

Ensure compliance with:

- Pollution control norms

- Fire safety regulations

- Local industrial permissions

Using waste biomass not only reduces pollution but also supports circular economy goals.

Conclusion

Setting up a biomass pellet plant is a future-ready investment combining profitability with environmental responsibility. With proper planning, quality machinery, and reliable raw material sourcing, a pellet plant can deliver consistent returns while contributing to a greener planet.

If executed correctly, biomass pellets truly represent a new hope and a new era of sustainable fuel 🌱🔥